Why Customer Love To

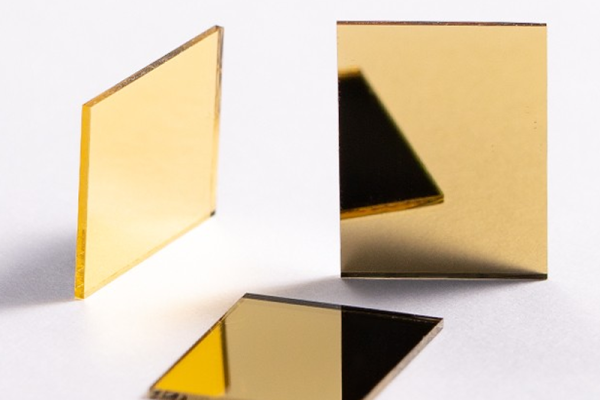

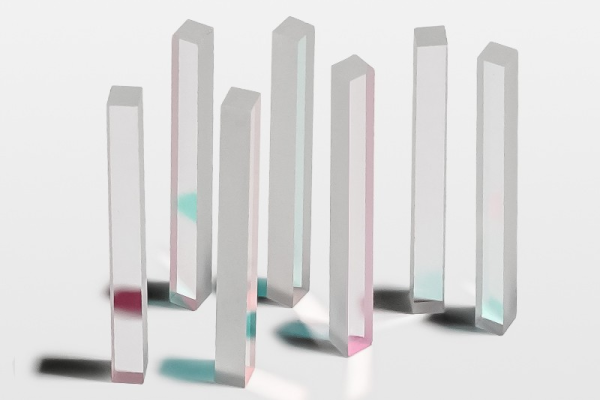

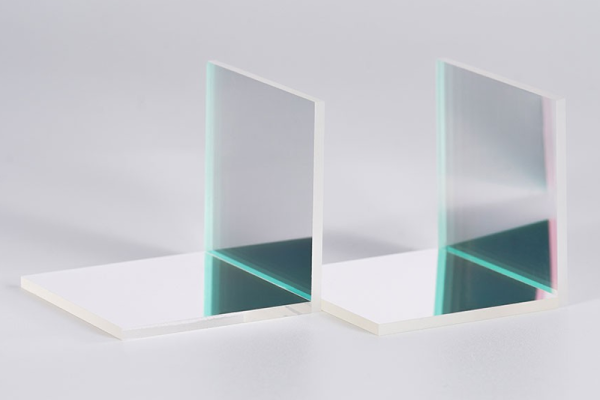

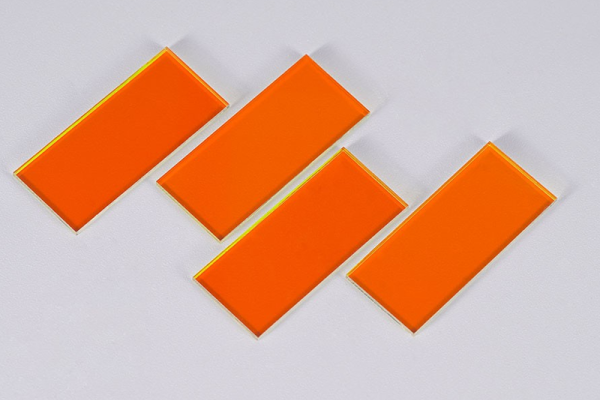

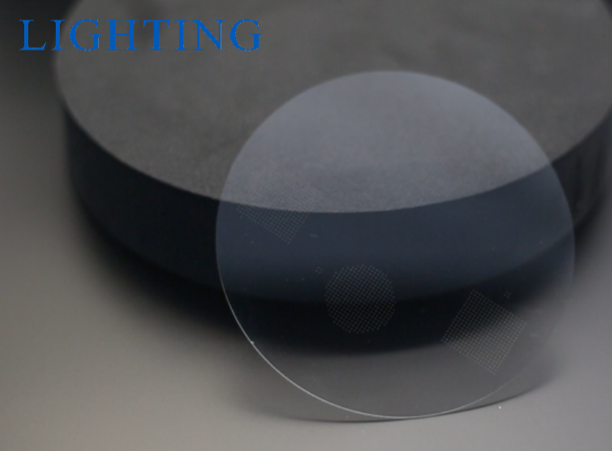

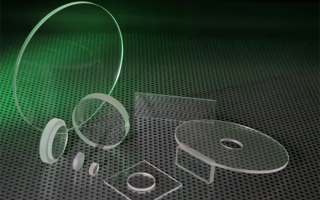

We have Corning® Eagle XG® , Corning® Pyrex® , SCHOTT BOROFLOAT®33 glass.Alkali-free glass, Aluminosilicate glass, Borosilicate glass, UTG glass. Can provide customers with glass cover plates, glass substrates, and glass with a thickness of ≧0.03mm and an overall size of ≧0.5mm.

Customized

Guangzhou Lighting Glass Co., Ltd. is a leading manufacturer and solution provider specializing optical glass products. As a trusted partner in the precision optics industry, we integrate R&D, manufacturing, and sales to deliver cutting-edge glass solutions for advanced technological applications.

Guangzhou Lighting Glass Co., Ltd. is a leading manufacturer and solution provider specializing optical glass products. As a trusted partner in the precision optics industry, we integrate R&D, manufacturing, and sales to deliver cutting-edge glass solutions for advanced technological applications.

Core Competencies:

Strategic authorized distributor for Corning® (USA) and SCHOTT® (Germany) premium optical glasses

Specialized in processing precision optical glass components

Full-range manufacturing capabilities from raw material to finished products

It is authorized dealer of Corning® Eagle XG® , Corning® Pyrex® , SCHOTT BOROFLOAT®33 glass.Alkali-free glass, Aluminosilicate glass, Borosilicate glass, UTG glass.

Can provide customers with glass cover plates, glass substrates, and glass with a thickness of ≧0.03mm and an overall size of ≧0.5mm.

Our latest outdoor smart terminal required a protective cover glass combining high strength, high hardness, and good light transmittance. After multiple rounds of testing and screening, we finally selected Aluminosilicate Glass from Guangzhou Lighting Glass Co., Ltd. Its high surface Mohs hardness provides excellent scratch resistance; more importantly, its flexural strength and impact resistance far surpass ordinary glass. During stringent whole-device drop tests, the pass rate for prototypes using this cover glass increased dramatically. Machinability also met requirements, with stable yield after CNC and tempering. It provides powerful assurance for our product durability, and end-customer feedback is excellent!

— Director Zhao, Product Division, from a Smart Hardware Company in Dongguan

When procuring new beakers, measuring cylinders, and reaction vessels for the lab, we specifically chose Borosilicate Glass (Type 3.3 material) from Guangzhou Lighting Glass Co., Ltd. After over six months of use, the experience has been excellent! Whether exposed to strong acids/bases or directly heated over an open flame (following safety protocols), the glass has performed remarkably stably, showing no signs of erosion, devitrification, or shattering. Its low coefficient of thermal expansion and strong resistance to temperature differentials greatly enhance safety. The glass itself is highly transparent with clear markings. Worth every penny – we'll continue purchasing for teaching and research.

— Professor Chen, from a University Chemistry Lab in Guangzhou

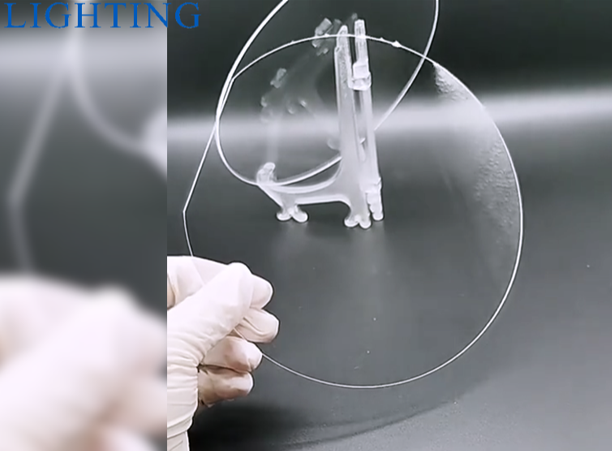

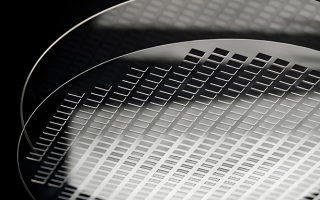

As temporary bonding carrier substrates for MEMS devices, we have near-critical requirements for surface flatness, roughness, cleanliness, and thermal stability of glass wafers. The Wafer Glass (150mm size) provided by Guangzhou Lighting Glass Co., Ltd. perfectly met our needs. Its ultra-smooth, defect-free surface effectively reduced particle contamination during processing, and its thermal expansion matching was also excellent, significantly improving the yield of subsequent debonding processes. The supplier precisely understood the specifications and provided detailed, credible test reports. A trustworthy supplier of precision materials.

— Dr. Zhang, from a MEMS Chip R&D Company in Suzhou

Our high-temperature industrial ovens demand extreme thermal shock resistance (>500°C to room temperature cycling) from the door viewports. Glass used previously frequently cracked, leading to high maintenance costs. Since switching to Heat-Resistant Glass from Guangzhou Lighting Glass Co., Ltd., the problem is completely solved! This glass has endured nearly six months of intense production testing without any cracking or deformation, and light transmittance remains excellent. Its resistance to rapid temperature changes is truly impressive, significantly reducing our downtime and spare parts costs. Excellent value for money!

— Manager Wang, from an Industrial Oven Manufacturer in Foshan

We had been searching for glass substrates with low dielectric constant and high insulation for precision sensors. The test results of the Alkali-Free Glass samples from Guangzhou Lighting Glass Co., Ltd. were a pleasant surprise! Its extremely low alkali metal content ensures excellent electrical insulation and chemical stability, and its coefficient of thermal expansion fully met requirements. After bulk purchasing, the product's consistency and stability have been outstanding, significantly improving the performance and reliability of our equipment. Supplier communication is smooth, logistics are punctual – a truly professional partner!

— Engineer Li, from an Electronic Equipment Manufacturer in Shenzhen